Question

How do I define protocol tolerances when using the SMARTSCAN feature of myQA Accept?

Answer

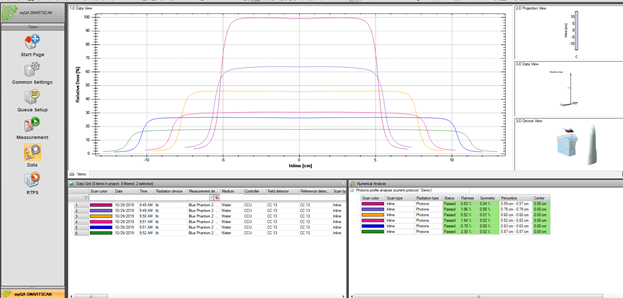

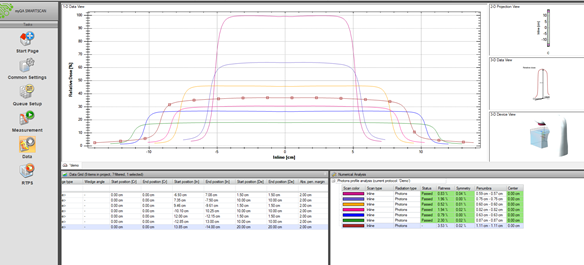

One of the major benefits of the SMARTSCAN SW is the immediate feedback during scanning that shows whether the scan is within specified tolerances. No need to open past data or flip through binders to see if your scan values fit what you expect.

In the photo below, the data analysis is showing green for the scans completed as they are within the predefined tolerance values for the expected numerical analysis results:

Step 1

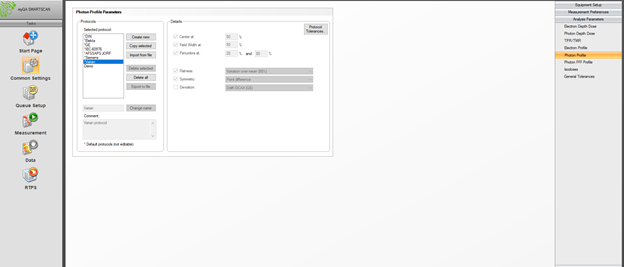

To set these protocols, first go to Common Settings > Analysis Parameters. There are analysis parameters for all different scan types. The templates are marked by an asterisk (*). These are predefined and cannot be edited. The user can create a new protocol or copy a protocol from an existing template. Once a new protocol or copied protocol is created, the user can define the analysis parameters used and rename the protocol. The selected protocol is what will be used for the analysis parameters in the Data tab.

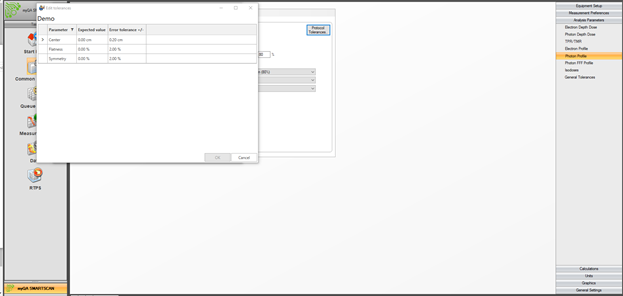

In this example a Photon Profile protocol is created named “Demo”.

Step 2

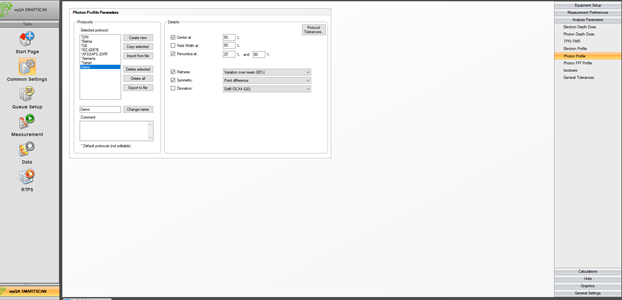

Now we can set the expected values and tolerances for photon profiles. Select the Protocol Tolerances button on the top right corner of the Details box.

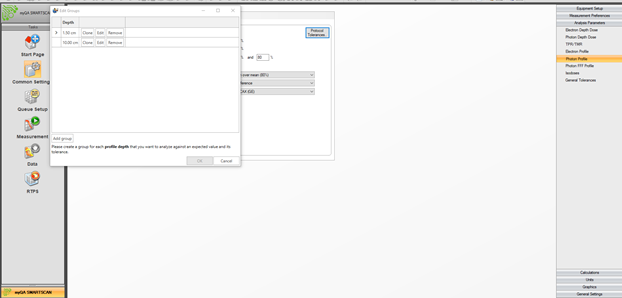

For Photon Profiles, each group of tolerances is based on the depth of the scan. Create a group for each depth. Click Edit on one of the groups.

Step 3

Now you can enter the expected values and the tolerances you’d like to use. Please note that the parameters used for the protocol depend on which boxes you have checked for the protocol in the details section. For this protocol Center, Flatness, and Symmetry are checked in the details section. Please note that for the 2019-001 version of Accept, the profile analysis protocol groups are not differentiated by field size. This means that if you leave Field size checked in the details, the expected field size will change, but there is no way to account for it in the protocols in this version of the SW. This issue will be fixed on future release, but for the 2019-001 version, please keep the Field Width out of the details, or leave the expected value blank.

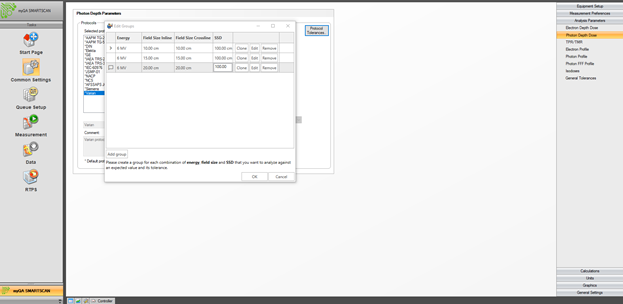

The process for creating depth dose protocols is very similar.

For depth dose protocols, the groups are defined by energy, field size, and SSD. Create a group for each different configuration, then click Edit.

For this protocol, R100 and D100 are used for analysis.

These protocols should be filled out for both electron and photon profiles and depth doses as well as for FFF profiles.

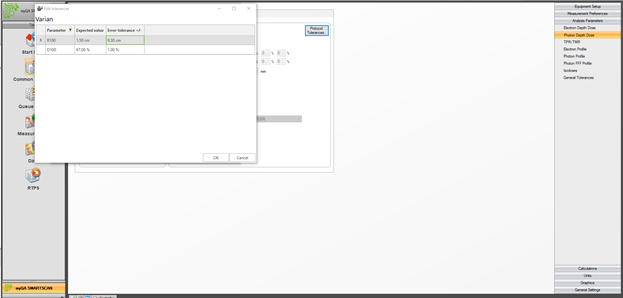

When a scan is taken, and a protocol tolerance is created for that scan, the data analysis will show red or green to show if the scan is within the prescribed tolerances. If the scan is white, then there is not a defined protocol for that scan.

Here you can see a scan that has no protocol created for it. It is a profile at 20cm depth and no photon profile was created for 20 cm depth

Step 4

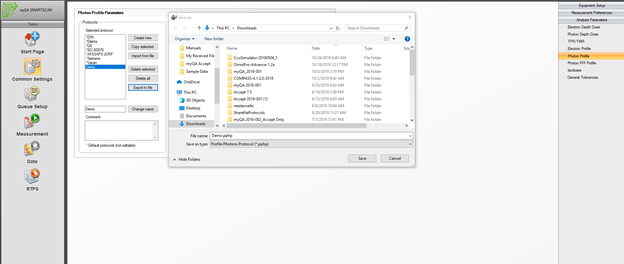

After the protocol tolerances are created for each scan type, it is highly recommended that these protocols are saved to a file. Next to each protocol, there is an option to export the protocol. Click Export and save each protocol.

Photon Profiles are saved as .pphp, electron profiles as .pelp, photon depth doses as .dphp, electron depth doses as .delp, and FFF profiles as .pphffp. After export, the tolerances can be imported using the Import from File option. Please note that the 2019-001 version of Accept is able to scan only Photons in SMARTSCAN. Electrons cannot be scanned in SMARTSCAN, but protocols can be created, and scans taken in “classic” Accept will show the pass/fail analysis in the data analysis tab. Also, previously taken data when opened in SW with protocols will show the pass/fail analysis.

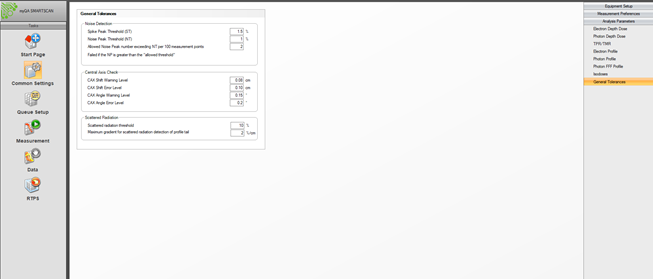

You may have noticed that in the Common Settings > Analysis Parameters, there is a section labeled General Tolerances

The first section, Noise Detection, is for setting thresholds on what is considered a noisy scan. The values shown are the defaults from the SW installation. During scanning in SMARTSCAN, the scans are determined to be good, bad, or suspicious. Good, being within tolerances, bad being outside tolerances, and suspicious, meaning that the scan was noisy, or backscatter was detected.

There are 2 ways a scan can be determined noisy. First, if any point along the scan has a deviation greater than the spike peak threshold (ST), the scan is determined noisy. For this example, if any point exceeds 1.5% deviation, the scan is defined noisy. Second, if the scan has a certain number of points defined by the “allowed noise peaks number” that exceed the “noise peak threshold” (NT), the scan is defined as noisy. For this example, if 2 points (allowed noise peak number) are greater than 1% (NT) deviation, the scan is defined as noisy and the scan will be marked as suspicious.

You can see the noise analysis outside of SMARTSCAN if you go to Data Handling > Smooth. The peak analysis will show if the scan was noisy or not.

The next section in General Tolerances is the CAX warning and error level. The CAX is done in the SMARTSCAN wizard. If the CAX analysis shows the CAX to be within the warning tolerances, the CAX is determined to be good and no correction is possible. It is recommended to change the CAX Shift Warning level to 0.01 cm. This way, the warning will always be tripped, and the user can see how much the CAX is off and to correct for it. Please note that the CAX check/correction cannot account for any angle deviation. The angle deviation will be displayed during CAX but the user is responsible for making changes to the setup to achieve an acceptable angle deviation. It is recommended to leave the warning and error tolerance of the angle deviation at standard. If the angle deviation is outside the error level, then the user will need to adjust the setup.

The last section is for Backscatter detection. The backscatter threshold is set at 10% as default and the gradient value is used by the SW to determine which portion of the scan is the profile tail. If there is backscatter detected, the scan in SMARTSCAN will be marked as suspicious.

All the analysis parameters and protocol tolerances have been set. Now it is time to load/create a queue and start scanning.