The procedure of creating CAX measurement queue for electrons is similar to the one for photons The difference is that only depth of 25 mm is needed to be measured, i.e., the queue only contains two items: inline and crossline profiles at 25 mm of depth.

This procedure is demonstrated with the Workflow for a 3D phantom, e.g., Blue Phantom2 or SMARTSCAN phantom, and photon radiation type.

The workflow to set up the CAX Measurement queue for the 2D phantom is similar to the one for a 3D phantom. However, the measurement and thus analysis are carried out only for one axis.

The Start and Stop points for depth dose measurements should be always chosen such that the measurement starts in the depth and ends slightly above the water surface.

Beginning from the water surface and scanning into the depth will falsify the measurement. This behavior is due to the water surface tension when the detector dives into the water.

To further improve the measurement accuracy, you may increase the Stabilization period time or decrease the Positioning speed in the Step by Step mode. The trigger settings can always be kept as given by default (recommended).

TMR

Enter and select all necessary parameters for the Field and equipment settings and Scan settings in the Basic settings area.

As during TMR measurements the Z axis of the phantom is deactivated and the TMR probe activated instead, and the software only will switch on/off the water pump, the settings are quite easy and less in the amount. You are only requested to enter the scan length (Depth) parameters.

TMR Measurements Setup General Procedure

1. If other measurements than TMR were done before, first empty the phantom so that about 15 cm of water remains. Otherwise fill the phantom until 15 cm water is inside.

These 15 cm are needed to provide correct backscatter conditions.

2. Lift up the phantom with the lift table, so that the LINAC isocenter (cross-point of the lasers) match the actual water surface.

3. Using the hand control, position the chamber to the actual water surface. The float which is running up and down on the linear transducer should sit on the water surface too. Only then a proper relation between the position values delivered by the Z potentiometer and the position values delivered by the float can be defined and maintained.

4. Using the hand control, re-define isocenter and water surface at the same point. The chamber is still sitting in the LINAC isocenter, which matches the actual water surface.

5. With this setup, the first measurement will start at the isocenter (after performing the 2 cm empty/refill procedure to stabilize the water surface), and the length of the scan is determined by either the entered scan length or the distance to the upper TMR limit, whichever is smaller.

Fanline

The Start and Stop points for Fanline measurements should always be chosen in the way that the measurement starts in the depth and ends slightly above the water surface.

Beginning from the water surface and scanning into the depth will falsify the measurement. This behavior is due to the water surface tension when the detector dives into the water.

To further improve the measurement accuracy, increase the Stabilization period time or decrease the Positioning speed in the Step by Step mode. The trigger settings can always be kept as given by default (recommended).

Inline/Crossline, Inline/Beam, Crossline/Beam (2D)

For big fields, it is recommended using the Continuous mode to save time. This is a considerable advantage of the measurement system consisted of Blue Phantom family and myQA Accept software.

However, for fields smaller than 5 cm × 5 cm, it is recommended to switch to the Step by Step mode (see Small Field Measurements).

Measuring with low energies at Dmax or close to the water surface, reducing the Scan speed will result in smoother curves in case of Inline / Crossline nets.

According to your preferences, you can either choose different Speed types for continuous measurements or different Step types for the step by step measurements to further increase the accuracy.

In the 2D settings choose the Step type according to the needed accuracy. It defines the steps between the single inline or crossline measurements within the measured net.

Standard step type is Equidistant. To get more accuracy, the Gradient step type is the best choice. Enter therefore Delta dose according to your needed accuracy level and the Large and Small steps. Also scan regions can be chosen. The software takes the one under Common Settings -Measurement Preferences - Scan Regions Setup of the defined Scan Steps to further improve the accuracy.

The Step distance defines the distance between the single scans within the net. The distance is equal for each measurement choosing the Step type “Equidistant”. However, it changes using the Gradient type, when the Delta dose level is reached.

Further improvements in accuracy can be achieved in increasing the Stabilization period time or decrease the Positioning speed in Step by Step mode. The trigger settings can always be kept as given by default (recommended).

3D Vector

The 3D Vector measurement offers the possibility to define a measurement from any point in the phantom to another arbitrary point.

For big fields, it is recommended using the Continuous mode to save time. This is a considerable advantage of the measurement system consisted of Blue Phantom family and myQA Accept software.

However, for fields smaller than 5 cm × 5 cm, it is recommended to switch to the Step by Step mode (see Small Field Measurements).

When you measure with low energies at Dmax or close to the water surface, reducing the Scan speed will result in smoother curves due to smaller water waves.

To further improve the measurement accuracy, you may increase the Stabilization period time or decrease the Positioning speed in the Step by Step mode. The trigger settings can be kept as given by default (recommended).

After finishing all necessary settings for a measurement queue, open the Queue panel if not already open. Press the Queue button at the bottom of the Content area.

To transfer the definition of your Queue entries into the Queue panel, press Add item and you will find your Queue in the panel.

The description of the Queue panel is privied in Section 4.4, myQA Accept Reference Guide.

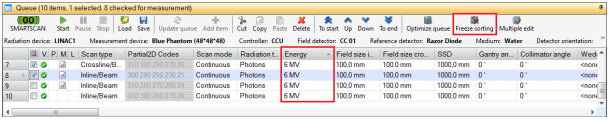

Optimize Queue

By pressing the Optimize queue button, a window opens giving the possibility to define the sorting order. As per your definition the queue items will be optimized.

Aim is not to have too many pauses between the queue items. This function arranges the queue items for example for same energies, field sizes in order to keep interruptions of the measurements due to field size changes or energy changes as low as possible. Out of the Available parameters, select the first sort criteria and move it into the Optimize/Sort order area by pressing the arrow button. Choose whether the sorting shall be done Ascending or Descending. Confirm by pressing the OK button.

Figure 1. Queue Panel – Optimize Queue

Imagine the situation of having defined Inline scans for 6 MV and 10 MV and Crossline scans for 6 MV and 10 MV. After pressing the Energy field, the scans have been sorted for energy. First the 6 MV scans are listed and then the 10 MV scans.

If you would define a new scan with 6 MV, the new queue item would be embedded within the 6 MV scans. Pressing the Freeze Sorting button, the arrangement of the previously sorted queues remains, but the new 6 MV queue items will be added at the end of the queue grid.

Figure 1. Queue Panel

The Multiple Edit is a convenient mode to edit multiple queue items within the Queue panel at once.

For editing queues, it is just necessary to select the queue items you want to edit directly in the panel (hold Ctrl key down while selecting scans).

Then press the Multiple Edit button.

Assuming some scans has been defined, all for 6 MV energy. If you now would like to edit all (although only some of them are perhaps possible according to your selection), press the Multiple Edit button.

Doing so, an additional line appears for editing.

Figure 1. Queue Panel – Multiple Edit mode

In this example, to change the energy for all queue items, click with the left mouse button into the line above the energy column. A drop down field appears giving the choice between all energies available for the selected Linac 1. By selecting 18 MV, the energy setting of all the selected queue items will be changed to 18 MV.

Figure 2. Queue Panel – Multiple Edit mode

In this way it is possible to edit all parameters in the Queue panel for selected queue items.

Saving Queues

To avoid the need to define every time similar queues, you can save and open them. E.g. for monthly QA measurements, you might want to measure always the same scans.

Going to the File menu click to Save Queue As….

Important: back-up data

Please make sure to back up data files and queues on a save place (e.g. server).

A standard Save As window appears, where you enter the name and select the storage location. The file format is *.opaq.

Opening Saved Queues

To open a stored queue, go to the File menu and click Open Queue….

A standard Open window is displayed, where you can choose the queue to be opened, and then confirm with pressing the Open button. The queues are available now in the Queue Setup view and the Measurement view. The RFQ format used with the OmniPro Accept 6.X can also be opened with myQA Accept.

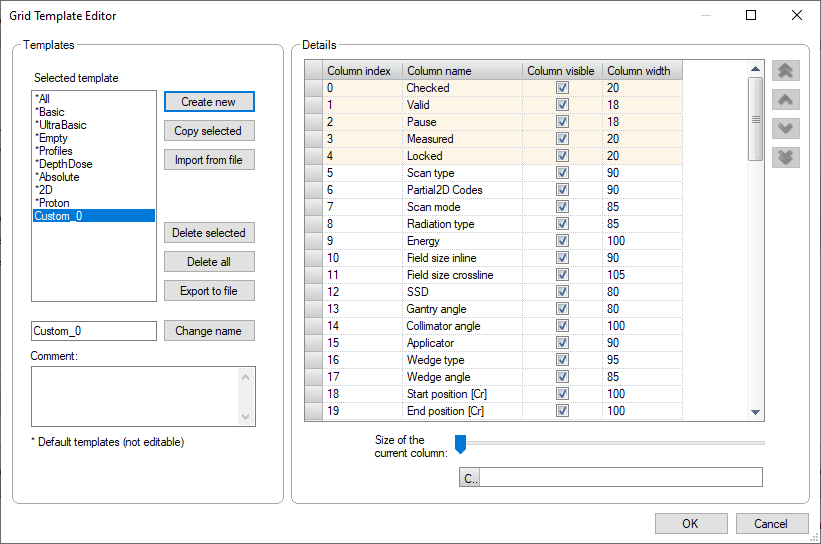

Grid Template Editor

By selecting the Template editor... from the context menu, you can create your own grid following your preferences.

Figure 1. Queue setup – Grid Template Editor

: Floating pin. Click this pin, the panel becomes fixed

: Fixed pin. Click this pin to remove the panel.