Question

How do I get started scanning w/ myQA Accept & BP2?

Answer

Step 1

To start scanning with myQA Accept, the CCU will need to be connected to the SW. With the CCU connected via Ethernet, open myQA Accept and go to Common Settings > Equipment Setup > Controllers. The IP address of the CCU should be showing. If it is not highlighted grey, click on the IP address.

The Electrometer type should be marked as Internal unless using the LDA-99. This step in Common Settings is only necessary if connecting to the CCU for the first time, or if there are multiple CCUs used on the same PC.

Step 2

Click the Connect button in the Controller panel in Queue Setup.

If no IP address in the Common Settings > Equipment Setup is displayed and the “Connect” button in the Controller panel is grayed out, there is either a firewall or IP address issue.

Step 3

After connecting to the CCU, check to see if the Gantry Coordinates button has the green check mark.

If the Gantry Coordinates button does not have the green check mark, the isocenter and water surface have not been set. Please set isocenter and water surface on the hand pendant.

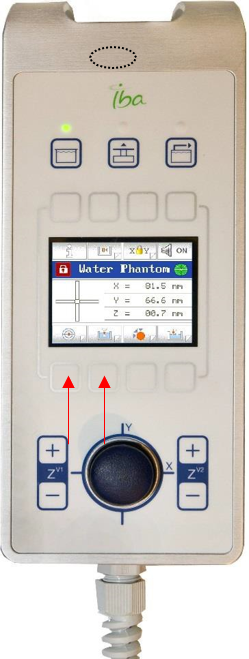

The Isocenter and Water surface buttons are marked with arrows here:

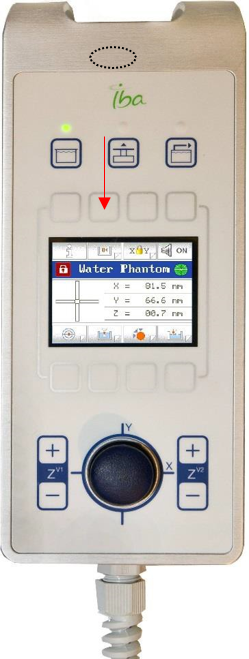

The Zero Position menu is here:

Do not set Isocenter or Water surface using the Zero Positions button. The Zero Positions button is used to set the center of travel for the mechanics of the tank. This position can be checked by referencing the coordinates on the hand pendant and the rulers on each axis of the tank. Drive each axis, x, y, and z to the 0 indicated on the ruler on the tank. If the hand pendant coordinates are off by more than 0.5 cm, please reset the 0 for that axis.

Step 4

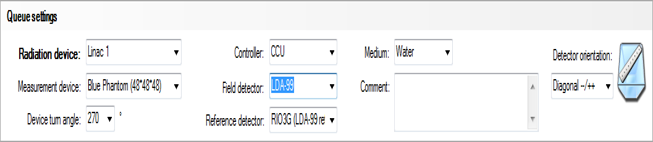

After verifying that the CCU and SW are communicating, verify that all fields in the Queue settings are correct for the current setup.

Step 5

The detectors selected in the Queue settings panel determine what bias voltage is applied. If a chamber is selected in this window pane, but a diode is connected to the CCU, and the HV Setup button is pressed, bias voltage will be applied. Please ensure all dropdowns in the Queue settings panel are correct.

Check that the Field detector and Reference detectors in the Controller panel are correct, then click the HV Setup button.

Step 6

The HV Setup button will briefly have a green check mark, followed by it going back to red. The Field HV and Reference HV will briefly show 300 V (or whatever voltage set for the detector in Common Settings). The voltage will drop to a lower number. Please do no click any buttons while the voltage is stabilizing. After about 15 seconds, the voltage should be +/- 10% of the voltage set in Common settings. The HV Setup button should also be green. If a diode is selected, the voltage will be off.

If the voltage never reaches +/- 10% of the expected value, there may be a short somewhere, swap triax cables and detectors to isolate the issue.

With the beam off, click the background button. There is a progress bar at the very bottom right-hand corner of the SW that will show the progress of the background.

After background has been set, the detector can be sent to the depth you wish to normalize at. There are 3 panels within the controller panel window. To move the detector, select the positioning panel.

Click the down arrow on the “Go to” button and enter the desired normalization position. Click the “enter” key twice. The first press closes the Go to window. The second sends the detector to the position. Alternatively, you can click the Go to button to get the detector to move.

To verify that the detector is moving, look at the picture of the tank in the Controller window. The black dot is the detector. You can also see the position coordinates. If the picture does not look like the physical setup, check the Zero Positions on the hand pendent referenced earlier.

Normalization can be done after scans are measured so the exact position of normalization is not critical.

With the detector is in position, turn on the beam and click on the Normalization button.

Step 6

If you are noticing that the signal bars for the field or reference detector are red, the detector is saturated. The sensitivity of the detector can be changed in the Electrometer panel in the field and reference tabs of the Control Panel as shown.

The input mode can also be adjusted here for field and reference. All IBA chambers should be in floated mode. All IBA diodes should be in grounded mode. When the detectors are selected in Common Settings > Equipment setup > Detectors, the input mode for IBA detectors is set automatically.

Step 7

Make sure the box on the left-hand side of the queue item is checked if you’d like to measure that scan.

Step 8

Turn the beam on and press the Start button. The SW will scan until there is a changed needed on the linac. When there is a change needed, a pop-up box will appear with the changes needed. Make the changes, then click Continue.

Step 9

High voltage on the CCU needs to be turned off when switching detectors. Disconnecting the CCU in the Controller Panel will not turn of HV. To turn off the HV, the user has two options:

-In the Controller Panel > Electrometer Panel, switch the Output to “Off” for both the Field and Reference. There is a tab for Field and Reference in the Electrometer Panel.

Verify that the HV is off for both field and reference detectors by checking the Controller Panel

Step 10

To save scans, click File > Save As/Save. The save button in the queue window is for saving a queue (.opaq file), not the beam data (.opab file).

More information regarding myQA Accept can be found in the myQA Accept User Manual.