Question

How do I set up scan queues in myQA Accept?

Answer

Step 1

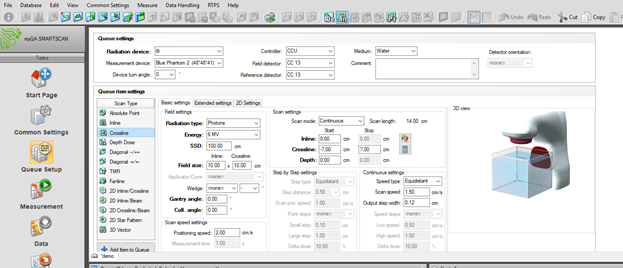

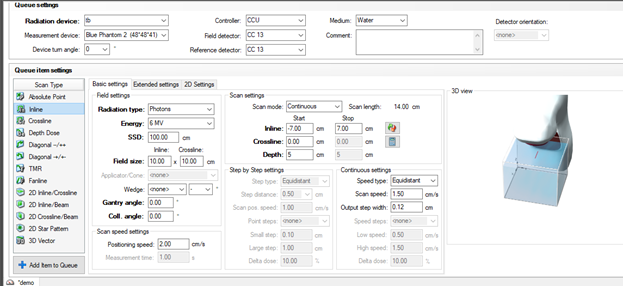

To perform scans, a scan queue needs to be created. Go to Queue Setup. Towards the top is Queue Settings. Ensure all information is correct. If any boxes are red, the information hasn’t been entered in for the Equipment Setup in Common Settings. That will need to be done first. In this example, the Blue Phantom 2 is selected with a turn angle of 0 and 2 CC13s are being used.

Step 2

Just below the Queue Settings, are the Queue settings. Start by selecting the type of scan. If you are unsure of the scan type, the 3D view window can be manipulated and the scan path is shown in red.

Enter all the relevant items into the queue item settings and either click the Add item to Queue, or the Add item button. Both serve the same function.

Step 3

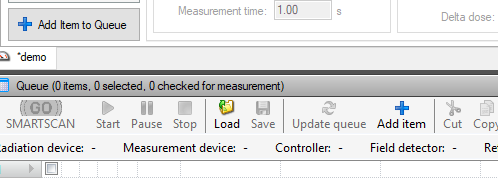

Please note: the save button next to the “Add item” button, does NOT save the beam data. This button is used to save a queue to a file and saves as a .opaq file. Beam data is saved by File > Save (as) and is saved as a .opab file.

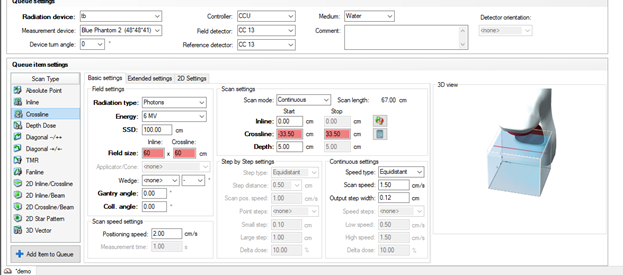

The Queue item settings will be red to indicate something is wrong. For example, if the field size exceed what is capable of the tank, the relevant fields will be red. Note that the scan path is also outside the tank. It is also possible to have red items in the queue settings if a queue from another computer is loaded and the equipment at your site does not match the equipment at the other site. Simply select the dropdowns that are red and select the equipment being used or enter it in common settings if needed.

The scan can be added to the queue with invalid items, but if you hover your mouse over the queue item, it will say invalid but measurable. The scan can be taken, but the message is warning the user that the measurement will not be measuring for the full length. This can also happen on depth dose scans. The depth of the scan is determined by where isocenter and water surface are set. If there is not enough water, then the scan can only go so deep. The default scan depth for depth doses is 31 cm. If there is red in the queue for this item, you likely need to change the starting depth to be shallower, or you need to add more water and reset watersurface and isocenter.

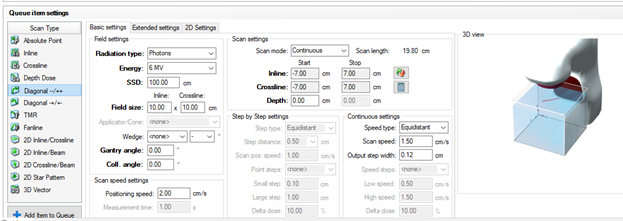

For virtually all scans, the Basic settings are all that need to be edited. For profiles, by entering the field size, the start/stop inline/crossline coordinates are automatically populated based on the Penumbra margin specified in Common Settings > Measurement Preferences > Scan Preferences. The depth will need to be specified.

Step 4

Position speed can be left at default and will have no affect on scans. The two scan types are Continuous and Step by Step. By selecting one, the other will be greyed out. Please note: if the user intends the queue to be run in SMARTSCAN, the scan must be Scan Mode: Continuous, Speed Type: Equidistant. For continuous scans, equidistant means that the scan will be a constant speed throughout the scan. Many users with experience have found scan speeds of about 0.75 cm/s to be a good balance between speed and quality of scans. This speed should work for profiles and depth doses of field size 3x3 cm and greater. For very small fields, it would be recommended to use a slower continuous speed or step by step.

Step 5

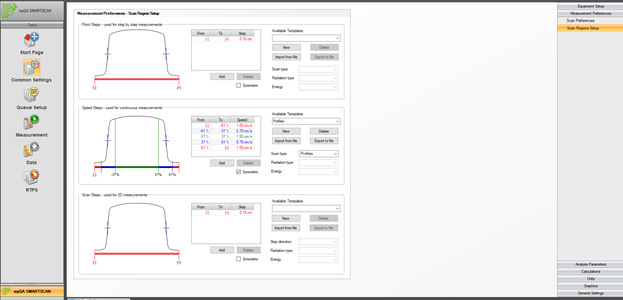

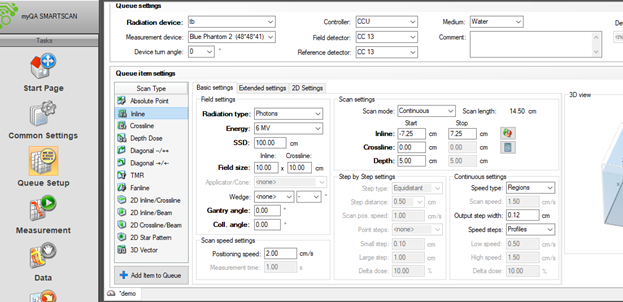

The user also has the option to create templates that vary the scan speed throughout the scan. Equidistant would be set to Regions, and the user would need to define templates in Common Settings > Measurement Preferences > Scan Regions Setup. Once a template is created for either a profile or depth dose and for either continuous or step by step, the template can be selected. Here is an example of a scan speed template for a continuous profile and it is named Profiles.

Step 6

In Queue Setup > Continuous Settings, the speed type is set to Regions and the Speed Steps template “Profiles” is selected.

More information on setting up scan regions can be found in the myQA Accept User Guide setion 5.2.2.2 Scan Regions Setup. However, for practical purposes, a scan speed set to equidistant, and around .75 cm/s should achieve good results.

Step 7

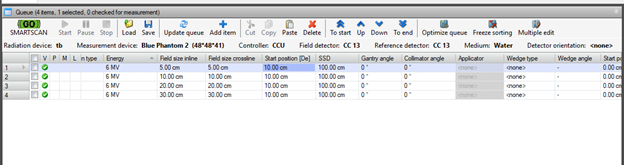

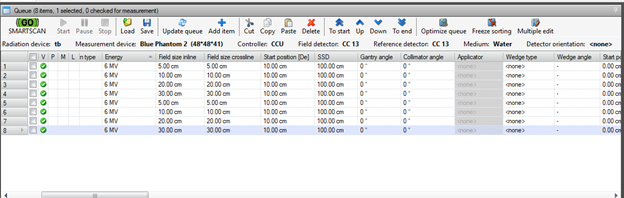

f creating a queue from scratch, there are techniques that can be used to speed up the process. For example, if a queue needs to have inline and crossline profiles for different field sizes, depths, and energies, a good option is to start with the inline profiles of one energy. In the image below, a queue was created for 6MV for 4 different field sizes at one depth. (Note: the columns in the queue can be dragged left and right to customize your view)

Step 8

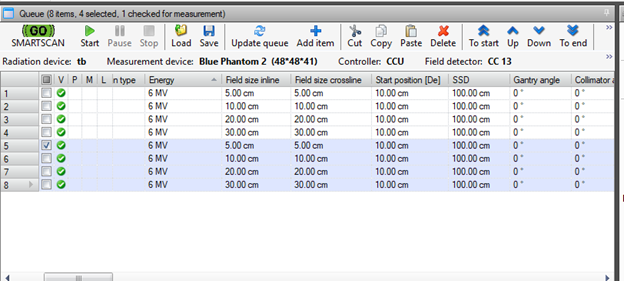

If the same scans are needed, but at a different depth, I can select all the scans by selecting the top scan, hold the shift key, and click on the bottom scan. Alternatively ctlr + a will work. You can also hold the Ctlr key while clicking scans to pick out individual scans to be highlighted. With the scans selected, click the copy button, or Ctrl + C, and click paste.

Step 9

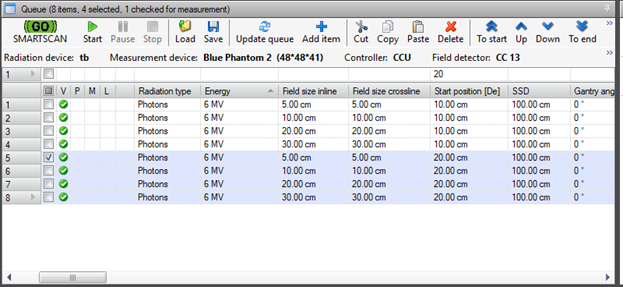

The bottom 4 scans are now duplicates. Select those, then select the Multiple Edit Button. You may need to click the top >> button, shown here next to the “To end button”:

Step 10

With the Multiple Edit button selected, there is a new column bar above the queue items. Select the duplicate scans and change the depth.

Step 11

To add more depths, copy 4 of the scans at one depth, paste, then use multiple edit to change the depth. Once you have all depths, you can copy all the queue items, paste as duplicate, then change the duplicate scans from inline to crossline. Once that is done, you should have all the profiles you need for one energy. Continue this process for different energies, scan types, depths, etc. Once done, click the save button to save the queue as a .opaq file.

If using SMARTSCAN, the queue does not need to be optimized as the SW does that. If using the traditional Accept SW, it would be a good idea to optimize. Next to the Multiple Edit button (which you may have to press the >> button for), there is the optimize queue button. Here you can choose which parameters you’d like to sort based on.

Step 12

One final note, if anything is marked red, there is usually a traceable issue. It could be that the equipment from the queue loaded does not match what is in Common Settings. Either enter it in common settings or select the equipment that is listed already in Common settings. If a scan item is red, scroll through the columns and locate which one is causing the issue. It could be that the scan is outside the limits. For example if you have a depth dose selected, and you are connected to the CCU, but isocenter and water surface are not set, the queue item will be red because the SW does not know how far down the detector can travel. So in this case, set isocenter and water surface, then re-evaluate if the requested scan length/depth will be possible given the current tank setup. The 3D View in the Queue setup is very helpful in visualizing the scan path and determining what might be causing issues.

IBA Dosimetry Service & Support