Question

How to limit the effect of hysteresis in your scanned data?

Answer

The Hysteresis effect can occur when conducting scans in both directions in continuous mode. This can contribute to the variance in data and is the result of signal processing within the system. Scan speed and step size are two factors that can lead to this effect being visualized in scanned data. Below are steps to minimize this effect in your scanned data.

Step 1

Use the step by step scanning mode. Optimal step size: 0.3 mm to 0.5 mm.

Step 2

Use the continuous scanning mode. Optimal scanning speed: 6 mm/s to 8mm/s.

Step 3

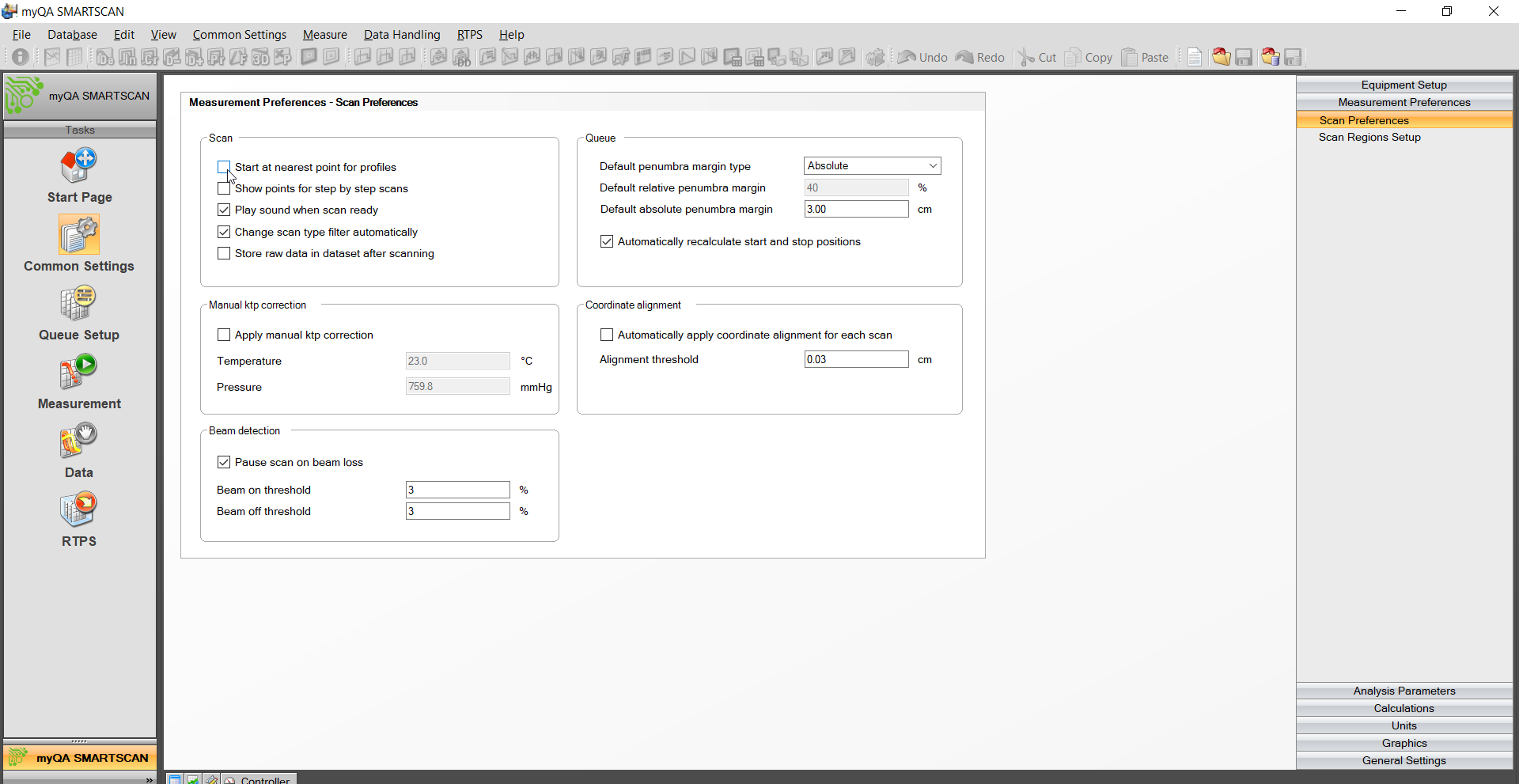

When using continuous scanning mode. In common settings under the measurement preference tab uncheck the box for start at nearest point for profiles.